Welcome to Shandong Charming Steel Co.,Ltd !

Tel : 0086 18264535555 E-mail : cmgc@sdcmsteel.cn

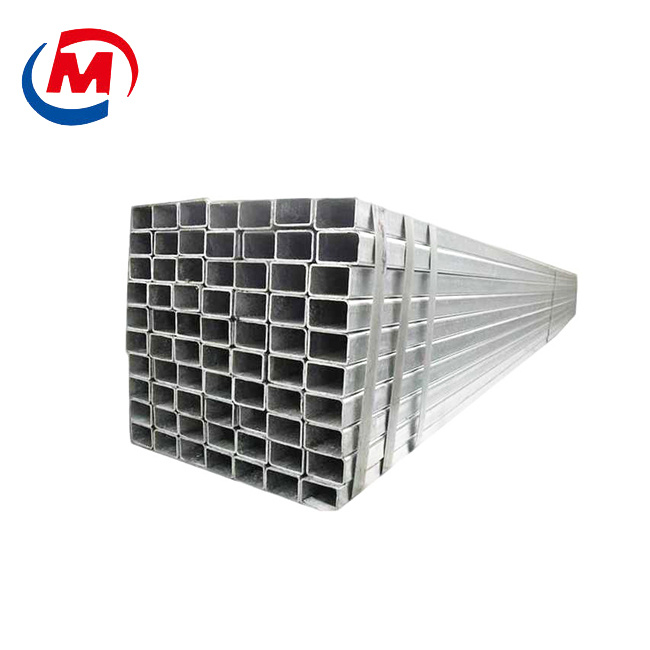

Classification and function of galvanized steel tube

The galvanized steel tube is divided into cold galvanized steel tube and hot galvanized steel tube. The hot galvanized steel tube is to make the molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the plating layer are combined. Hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after the pickling, it is cleaned in a tank of ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to In the hot dip plating tank. Hot galvanized steel tube has the advantages of uniform coating, strong adhesion and long service life. The hot galvanized steel tube matrix undergoes a complex physical and chemical reaction with the molten plating solution to form a corrosion-resistant zinc-iron alloy layer with a compact structure. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix, so its corrosion resistance is strong.

The cold galvanized steel tube is electro-galvanized, and the amount of galvanization is very small, only 10-50g/m2, and its corrosion resistance is much different than that of the hot-dip galvanized tube. Formal galvanized steel tube manufacturers, in order to ensure quality, most of them do not use electro-galvanized (cold plating). Only those small enterprises with small scale and outdated equipment use electro-galvanization, and of course their prices are relatively cheaper. The galvanized layer of cold galvanized steel tube is an electroplated layer, and the zinc layer is layered independently of the steel tube substrate. The zinc layer is thin, and the zinc layer simply adheres to the steel pipe substrate and is easy to fall off. Therefore, its corrosion resistance is poor. It is prohibited to use cold galvanized steel tubes as water supply pipes in new houses.

The galvanized steel tube has a welded steel pipe with a hot-dip galvanized or electro-galvanized layer on the surface. Galvanizing can increase the corrosion resistance of the steel pipe and prolong its service life. The galvanized steel tube has a wide range of uses. In addition to being used as line pipes for low-pressure fluids such as water, gas, and oil, it is also used as oil well pipes and oil pipes in the petroleum industry, especially offshore oilfields, as well as oil heaters and condensation for chemical coking equipment. Pipes for coolers, coal-distilled wash oil exchangers, pipe piles for trestle bridges, and pipes for support frames in mine tunnels, etc.

galvanized,steel,tube,quality,galvanized,steel,tube,Wholesale,galvanized,steel,tube,galvanized,steel,tube,factory

Previous Page

RELATED NEWS

What can painted galvanized steel coil materials do

The main application industries of painted galvanized steel coils: a large number of galvanized sheets are used in automobile manufacturing, refrigerators, construction,

2022

06-23

How to store pre-painted galvanized steel coil products

Pre-painted galvanized steel coils should be stored in a dry and ventilated indoor environment to avoid open storage. Condensation is very likely to occur in places with large temperature differences.

2022

06-27

Recommendations for the selection and use of pre-painted galvanized steel coils

The color-coated steel plate using pre-painted galvanized steel coil as the substrate, in addition to zinc protection, the organic coating on the zinc layer plays a role of covering and isolation

2022

06-29

Pre-painted galvanized steel coil installation depends on what to fix

Pre-painted galvanized steel coils can be installed in two ways: penetrating and concealed. Penetrating fixing is the most common way to install pre-painted galvanized steel coils on roofs and walls,

2022

07-01

ONLINE MESSAGE