Welcome to Shandong Charming Steel Co.,Ltd !

Tel : 0086 18264535555 E-mail : cmgc@sdcmsteel.cn

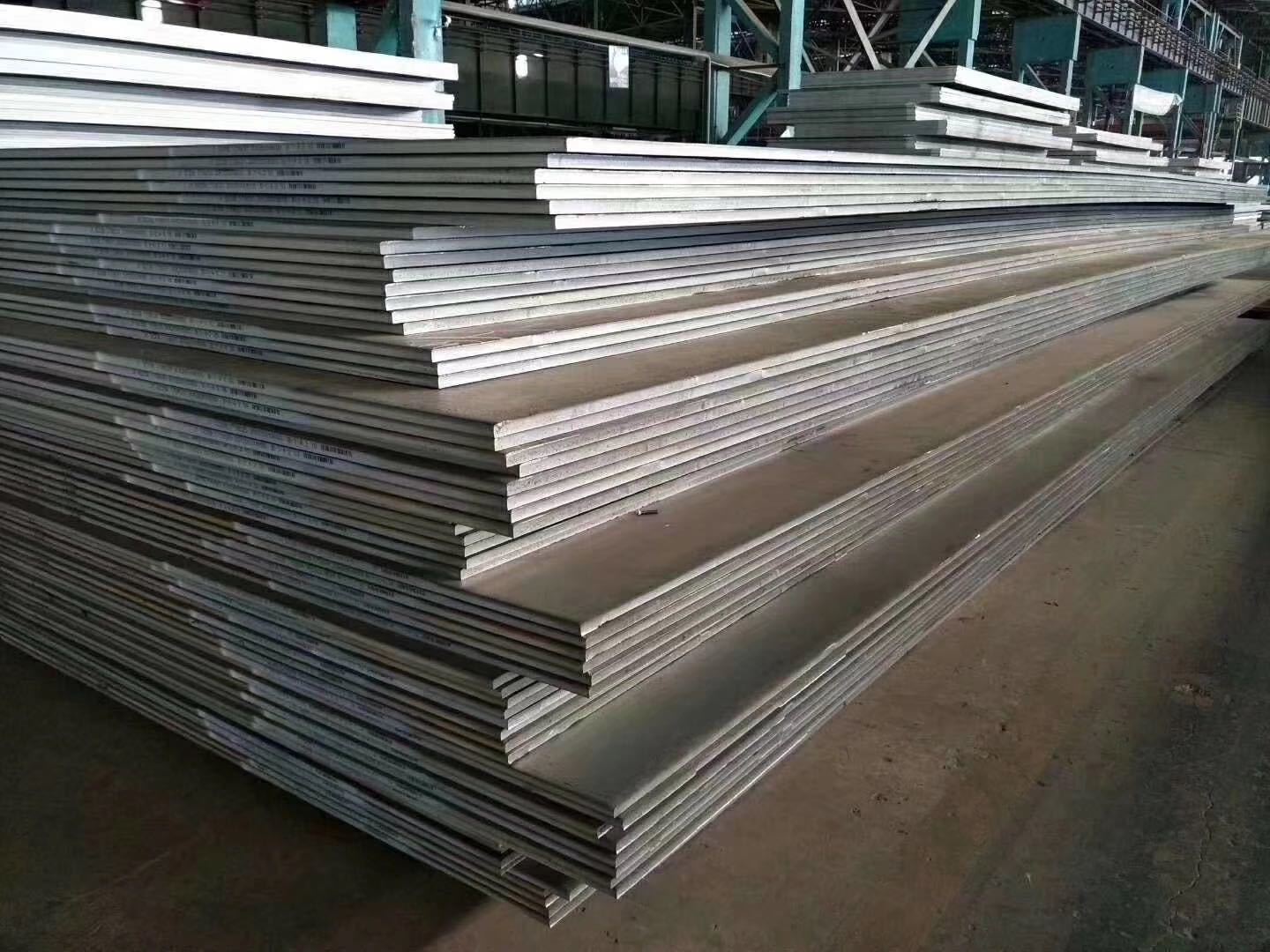

Wear resistant steel plate manufacturers tell you the welding characteristics of Wear resistant steel plate

Wear resistant steel plate is a new type of building material, and its welding process also has certain special requirements. Manual arc welding should use alkaline electrodes with low residual moisture. If necessary, the electrodes should be dried according to the requirements of the wear resistant steel plate manufacturer. For the implementation of high-strength Wear resistant steel plate welding, it is recommended to preheat the Wear resistant steel plate. The preheating temperature can consider the recommended value and refer to the welding specification. Note: Wear resistant steel plate weld filler should be within the allowable range of component load and weld wear. Soft welding consumables should be selected as much as possible. At the same time, pay attention to wear resistant steel plate and component preheating temperature must avoid exceeding 200 degrees Celsius, because too high temperature will reduce the hardness.

Preparation before welding of Wear resistant steel plate:

1: Wear resistant steel plate has a high carbon content and carbon equivalent, which is prone to welding cracks. The oxide, oil, rust and other debris on the surface of the workpiece should be carefully cleaned before welding;

2: The preparation of the groove is completed by mechanical processing, and it is required that there is no water, oil, rust and other impurities on both sides of the groove;

3: Try to avoid welding Wear resistant steel plate in the environment of draught, low temperature and high temperature.

Wear,resistant,steel,plate,manufacturers,Wear,resistant,steel,plate,supplier,Wholesale,Wear,resistant,steel,plate,china,Wear,resistant,steel,plate

Next Page

RELATED NEWS

Stainless steel plate plasma cutting process

Although stainless steel plates account for a relatively small proportion of world steel consumption, they are still vital to specific manufacturing industries such as the energy and food processing markets. At present, the global consumption of stainless steel plate materials is continuously increasing.

2020

11-11

Production process of welded steel pipe

The development of steel pipe production technology began with the rise of bicycle manufacturing, the development of petroleum in the early 19th century, the manufacture of ships, boilers, and aircraft during the two world wars, the manufacture of thermal power boilers after the Second World War, the development of the chemical industry, and The drilling and transportation of oil and natural gas have strongly promoted the development of the steel pipe industry in terms of variety, output and quality.

2020

11-11

Steel prices have risen by more than a thousand steel companies generally turn losses into profits

Since the first half of last year, steel prices have begun to recover thanks to a series of measures such as supply-side reforms and elimination of backward production capacity. Taking rebar as an example, the average price on March 9 last year was 2475 yuan/ton, and on March 9 this year, it has risen to 3852 yuan/ton, an increase of 35%.

2020

11-11

China Steel Association: Steel prices in the domestic market continued to rise slightly in September

According to data from the China Iron and Steel Association, in September, the domestic steel market demand was strong, and steel prices continued to rise. Affected by the rapid release of steel production capacity, pressure on the supply side has risen, and the price increase of steel has narrowed.

2020

11-11

ONLINE MESSAGE