Welcome to Shandong Charming Steel Co.,Ltd !

Tel : 0086 18264535555 E-mail : cmgc@sdcmsteel.cn

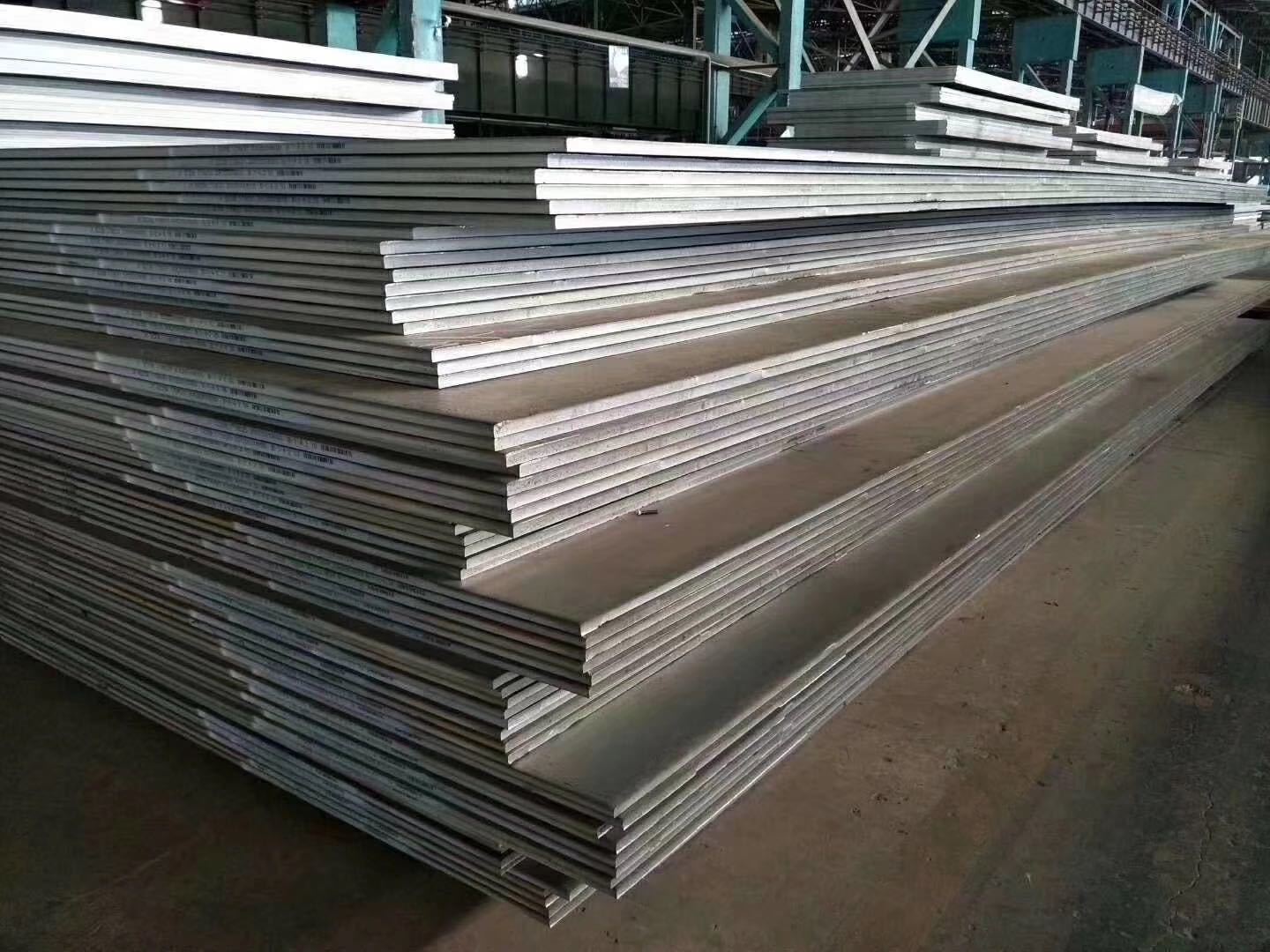

Wear resistant steel plate manufacturers tell you the welding characteristics of Wear resistant steel plate

Wear resistant steel plate is a new type of building material, and its welding process also has certain special requirements. Manual arc welding should use alkaline electrodes with low residual moisture. If necessary, the electrodes should be dried according to the requirements of the wear resistant steel plate manufacturer. For the implementation of high-strength Wear resistant steel plate welding, it is recommended to preheat the Wear resistant steel plate. The preheating temperature can consider the recommended value and refer to the welding specification. Note: Wear resistant steel plate weld filler should be within the allowable range of component load and weld wear. Soft welding consumables should be selected as much as possible. At the same time, pay attention to wear resistant steel plate and component preheating temperature must avoid exceeding 200 degrees Celsius, because too high temperature will reduce the hardness.

Preparation before welding of Wear resistant steel plate:

1: Wear resistant steel plate has a high carbon content and carbon equivalent, which is prone to welding cracks. The oxide, oil, rust and other debris on the surface of the workpiece should be carefully cleaned before welding;

2: The preparation of the groove is completed by mechanical processing, and it is required that there is no water, oil, rust and other impurities on both sides of the groove;

3: Try to avoid welding Wear resistant steel plate in the environment of draught, low temperature and high temperature.

Wear,resistant,steel,plate,manufacturers,Wear,resistant,steel,plate,supplier,Wholesale,Wear,resistant,steel,plate,china,Wear,resistant,steel,plate

Next Page

RELATED NEWS

ONLINE MESSAGE

Contact Us

Tel : 0086 18264535555

Email : cmgc@sdcmsteel.cn

WhatsApp:0086 18264535555

Add : Phoenix Industrial Park, Dongchangfu District, Liaocheng City, Shandong Province