Welcome to Shandong Charming Steel Co.,Ltd !

Tel : 0086 18264535555 E-mail : cmgc@sdcmsteel.cn

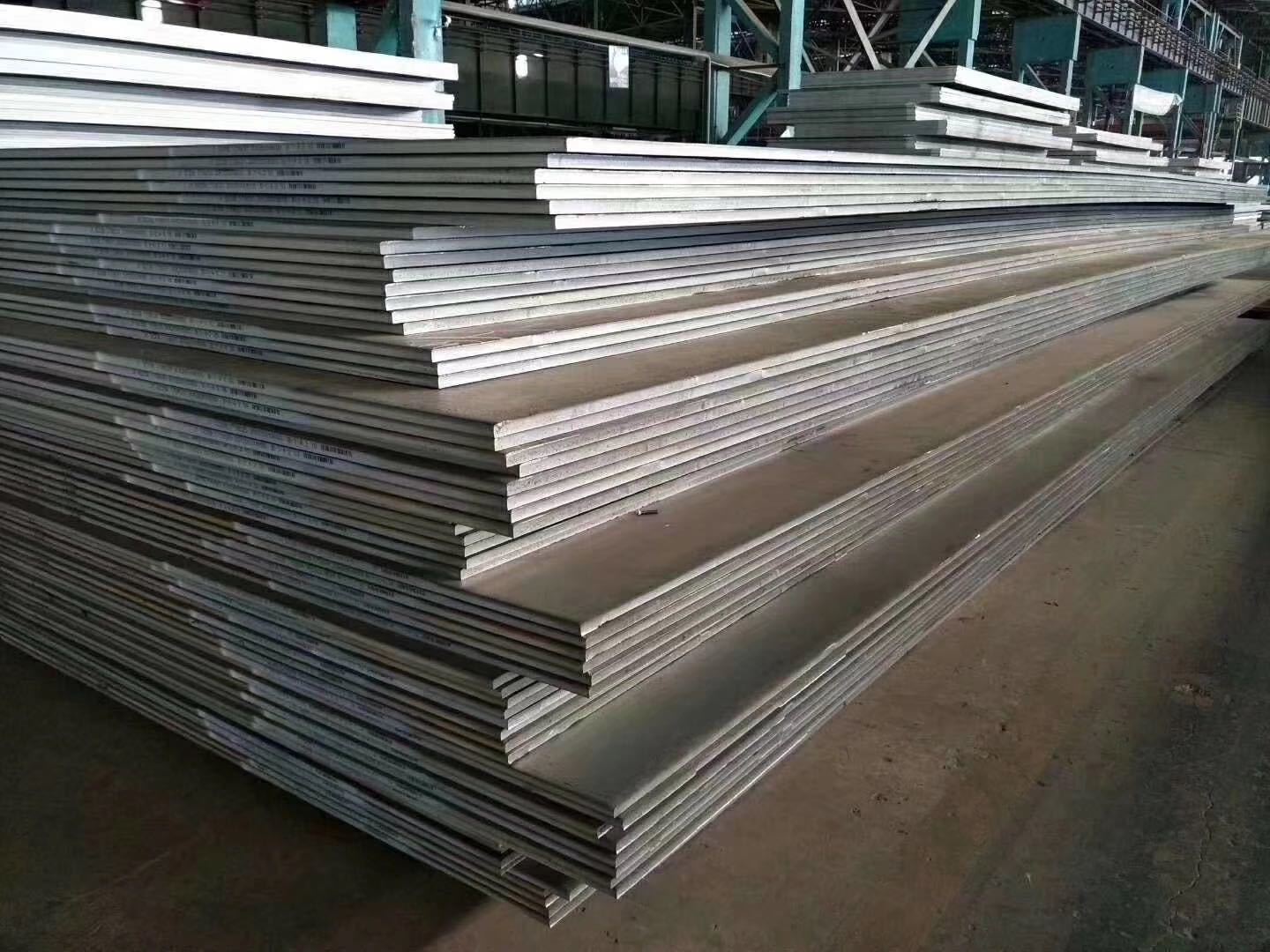

Wear resistant steel plate manufacturers tell you the welding characteristics of Wear resistant steel plate

Wear resistant steel plate is a new type of building material, and its welding process also has certain special requirements. Manual arc welding should use alkaline electrodes with low residual moisture. If necessary, the electrodes should be dried according to the requirements of the wear resistant steel plate manufacturer. For the implementation of high-strength Wear resistant steel plate welding, it is recommended to preheat the Wear resistant steel plate. The preheating temperature can consider the recommended value and refer to the welding specification. Note: Wear resistant steel plate weld filler should be within the allowable range of component load and weld wear. Soft welding consumables should be selected as much as possible. At the same time, pay attention to wear resistant steel plate and component preheating temperature must avoid exceeding 200 degrees Celsius, because too high temperature will reduce the hardness.

Preparation before welding of Wear resistant steel plate:

1: Wear resistant steel plate has a high carbon content and carbon equivalent, which is prone to welding cracks. The oxide, oil, rust and other debris on the surface of the workpiece should be carefully cleaned before welding;

2: The preparation of the groove is completed by mechanical processing, and it is required that there is no water, oil, rust and other impurities on both sides of the groove;

3: Try to avoid welding Wear resistant steel plate in the environment of draught, low temperature and high temperature.

Wear,resistant,steel,plate,manufacturers,Wear,resistant,steel,plate,supplier,Wholesale,Wear,resistant,steel,plate,china,Wear,resistant,steel,plate

Next Page

RELATED NEWS

Types and specifications of stainless steel flat bar

Stainless steel flat bar is a rectangular steel with slightly pure edges. The stainless steel flat bar can be semi-finished steel. There are cold drawn polished stainless steel flat bar and hot rolled acid white sandblasted stainless steel flat bar.

2021

06-30

Flattening and slitting process of stainless steel coil

The raw material processing of stainless steel coil before pipe making is also very critical, and every process is a factor that determines the quality of pipe fittings. Today, I will take you to learn about the flattening and slitting process of stainless steel coil panels.

2021

07-09

Related features of cold rolled steel coil

Cold rolling is made of hot-rolled coils as raw materials and rolled at room temperature below the recrystallization temperature. Cold rolled steel coils are steel coils produced through cold rolling processes.

2021

07-16

Precautions for application of Prepainted Galvanized Steel Coil

Prepainted Galvanized Steel Coil's exquisite surface and excellent quality have become a suitable choice for users in many fields. Because of the different uses, special attention should be paid to the application. So, what are the precautions when applying Prepainted Galvanized Steel Coil?

2021

07-23

ONLINE MESSAGE