Welcome to Shandong Charming Steel Co.,Ltd !

Tel : 0086 18264535555 E-mail : cmgc@sdcmsteel.cn

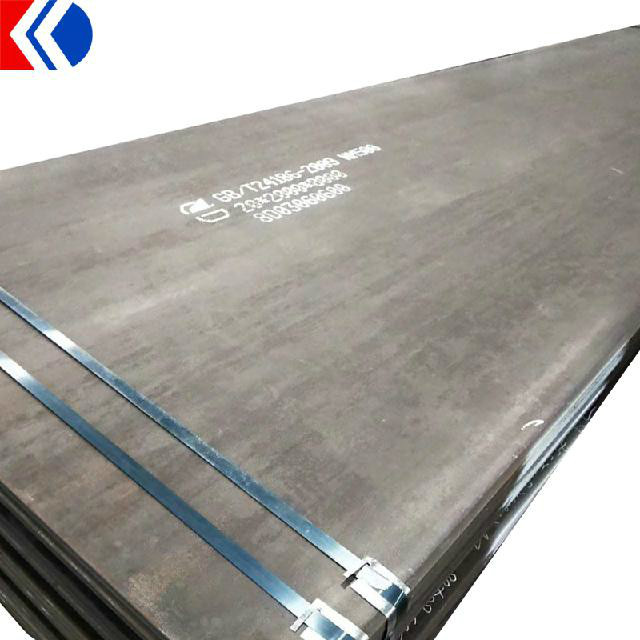

Production process of quality weather resistant steel plate

The quality weather resistant steel plate is made by adding phosphorus, nickel, copper and other trace elements to the ordinary steel plate during the smelting process. A dense, highly protective film is formed on the surface of the steel, which prevents the further diffusion of rust and protects the underlying materials. Slow down corrosion. The appearance of weathering steel plate is bare, and it can resist corrosion without using other coatings. It is environmentally friendly because it does not pollute the surrounding environment.

The production process of quality weather resistant steel plate: weathering steel is generally smelted into the furnace, including converter, electric furnace microalloying treatment, argon blowing refining, low superheat continuous casting, rare earth wire feeding, controlled rolling and controlled cooling. During smelting, scrap steel is added to the furnace along with the charge and smelted according to conventional methods. After the steel is discharged, deoxidizer and alloy are added. After the molten steel is blown with argon, the steel is cast immediately, and the molten steel with the argon temperature adjusted by the continuous casting machine is poured. plate. Due to the addition of rare earth elements in the steel, the weathered steel is purified, and the content of inclusions is greatly reduced.

Since the 1960s, China has been using quality weather resistant steel plate. Although it has been used for a long time, the development and production of weathering steel plates in China has not fallen behind. With the rapid development of the national economy, the application of weathering steel has been brought together by relevant domestic departments. Paying attention to the development and upgrading of weathering steel plates is of high practical significance and has an important impact on the structural upgrading of the steel industry.

quality,weather,resistant,steel,plate

RELATED NEWS

ONLINE MESSAGE

Contact Us

Tel : 0086 18264535555

Email : cmgc@sdcmsteel.cn

WhatsApp:0086 18264535555

Add : Phoenix Industrial Park, Dongchangfu District, Liaocheng City, Shandong Province