Welcome to Shandong Charming Steel Co.,Ltd !

Tel : 0086 18264535555 E-mail : cmgc@sdcmsteel.cn

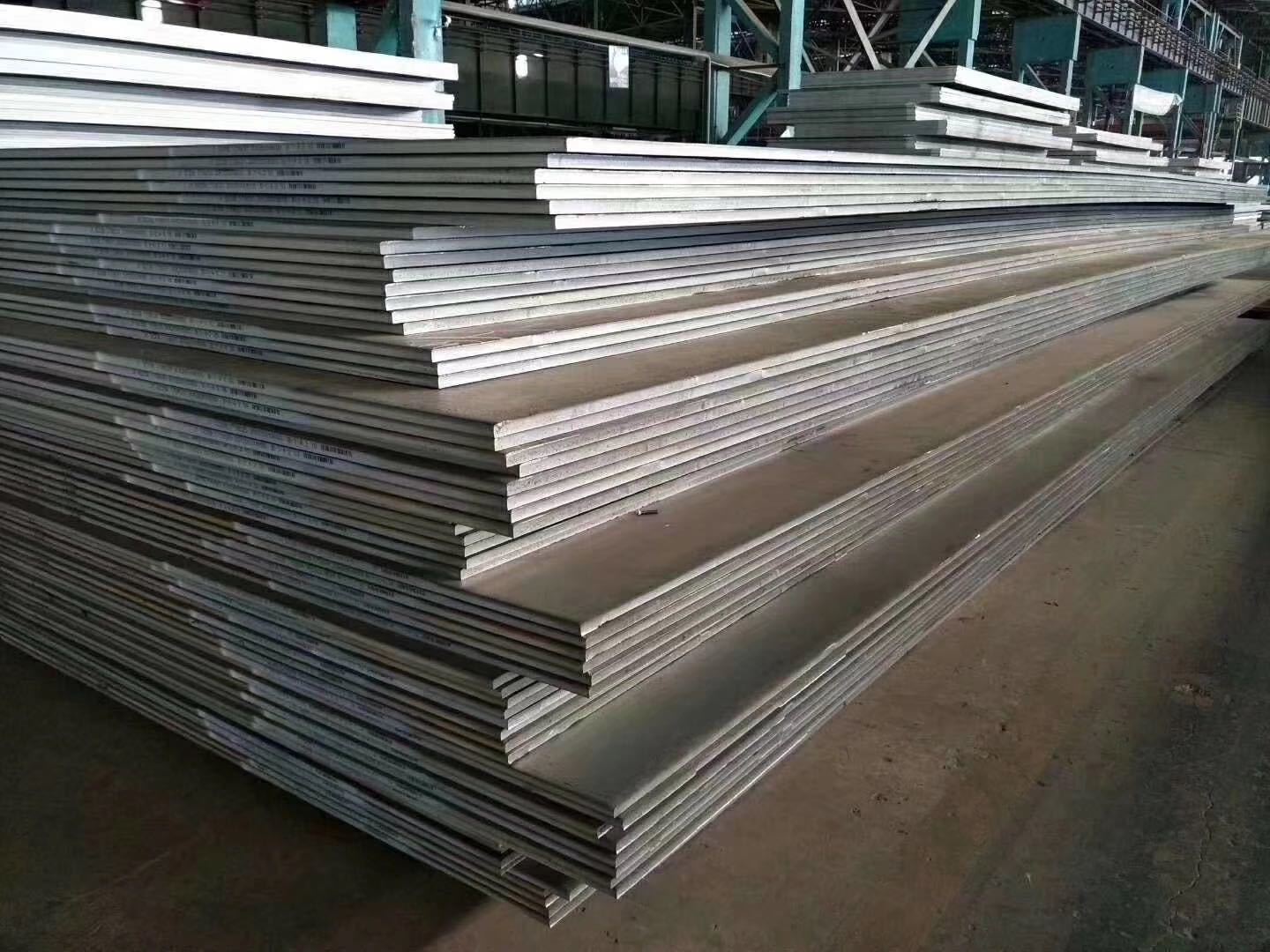

What should be paid attention to when sealing the wear-resistant steel plate

The pressure test of the wear-resistant steel plate can ensure that its shape can remain as it is, which can be selected according to the properties of the wear-resistant steel plate. When the wear-resistant steel plate is sealed, it is better to choose a better sealing material, because the sealing needs to ensure the wear resistance of the material on the edge. And it is best to sprinkle a layer of polymer, which can ensure the quality of the wear-resistant steel plate.

The new end face sealing device adopts high-strength polyurethane sealing material. Due to the application of electro-hydraulic proportional control technology, it can maintain proper sealing force and protect the sealing ring. This kind of sealing ring has a long service life, is more convenient to install, and greatly reduces the dead zone of the pressure test. Radial sealing method The radial sealing rubber ring of the test head is inside the wear-resistant steel plate.

In order to achieve the internal pressure and the wear-resistant steel plate wall contact seal, the sealing ring has a long service life, is more convenient to install, and greatly reduces the labor intensity, but the shortcomings of the wear-resistant steel plate pressure test have blind spots. A typical composite steel-lined tubing liner has a matrix of fiber-reinforced polymers that protect the steel matrix from corrosion. Corrosion of spacer rings, in particular, ensures that the corrosion-resistant lining ends between adjacent ones.

Wholesale,Wear,resistant,steel,plate,Wear,resistant,steel,plate,manufacturers,Wear,resistant,steel,plate,supplier

RELATED NEWS

The difference between seamed stainless steel pipe and seamless stainless steel pipe

Stainless steel pipe is a hollow long round steel, which is widely used in petroleum, chemical, medical, food, light industry, mechanical instrumentation and other industrial pipelines and mechanical structural parts. In addition, when the bending and torsion strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also often used to produce various conventional weapons, barrels, shells, etc.

2020

11-11

How to deal with oxidized white spots on stainless steel pipe fittings

White spots are formed on the surface, and corresponding treatment must be made at this time, but how should we deal with it?

2020

11-11

What is quality Prepainted Galvanized Steel Coil?

The quality Prepainted Galvanized Steel Coil is made of hot-dip galvanized sheet, hot-dip galvanized steel sheet, electro-galvanized sheet, etc. as the substrate. After surface pretreatment, one or several layers of organic paint are applied to the surface, and then baked and cured. product.

2021

03-26

Classification of Prepainted Galvanized Steel Coil

This article mainly introduces the classification and content of Prepainted Galvanized Steel Coil. I hope it will be helpful for you to understand Prepainted Galvanized Steel Coil.

2021

04-01

ONLINE MESSAGE