Welcome to Shandong Charming Steel Co.,Ltd !

Tel : 0086 18264535555 E-mail : cmgc@sdcmsteel.cn

ONLINE MESSAGE

Hot Sale Q235 Ss400 Q345 Q195 DC52D S235jr 2mm 4mm 6mm 8mm 10mm Mild Cold/Hot Rolled High Carbon Steel Coil

ss400 in ss400 carbon steel coil refers to the marking method for Japanese steel materials and a criterion, which is equivalent to domestic Q235 steel (also known as A3 steel). Foreign standard structural steels are often classified according to their tensile strength, such as SS400 (as marked in Japan), where 400 means that the minimum value of σb is 400MPa. Ultra-high-strength steel refers to steel with σb≥1373 Mpa.

Category :

Details description

Carbon steel coil product description

ss400 in ss400 carbon steel coil refers to the marking method for Japanese steel materials and a criterion, which is equivalent to domestic Q235 steel (also known as A3 steel). Foreign standard structural steels are often classified according to their tensile strength, such as SS400 (as marked in Japan), where 400 means that the minimum value of σb is 400MPa. Ultra-high-strength steel refers to steel with σb≥1373 Mpa.

carbon steel coil information

P: Below 0.050

S: Below 0.050

[Mechanical Properties]

Yield strength N/mm²

245 or more (a<16mm) 235 or more (16mm<a<40mm)

215 or more (a>40mm)

a: Steel thickness

Tensile strength N/mm²

400~510

About tensile strength

definition

During the tensile process of the carbon steel coil sample, the material enters the strengthening stage after the yield stage. As the size of the transverse cross-section of the tensile shrinks significantly, the maximum force (Fb) that the sample bears before breaking is divided by the original transverse cross-section of the sample The stress (σ) resulting from the cross-sectional area (So) is called the tensile strength or the strength limit (σb), and the unit is N/mm2 (MPa). It represents the maximum ability of metal materials to resist damage under tensile force.

Calculation formula

σ=Fb/So

In the formula: Fb-the maximum force that the sample bears when it is broken, N (Newton); So-the original cross-sectional area of the sample, mm2.

The tensile strength (Rm) refers to the maximum stress that a material can withstand before it breaks.

Universal material testing machine

When the steel yields to a certain extent, due to the rearrangement of the internal grains, its resistance to deformation increases again. Although the deformation develops rapidly at this time, it can only increase with the increase of the stress until the stress reaches the maximum value. After that, the ability of the steel to resist deformation was significantly reduced, and large plastic deformation occurred at the weakest point, where the cross-section of the test piece quickly shrank, and necking occurred until it was broken. The maximum stress value of steel before fracture is called the ultimate strength or tensile strength.

unit

kn/mm2 (kg force per unit area)

measuring

The most common method for measuring tensile strength in China is to use universal material testing machines to determine the tensile/compressive strength of materials!

With Q235

SS400 is basically equivalent to my country's Q235 (equivalent to Q235A). However, there are differences in specific indicators. Q235 has requirements for the contents of C, Si, Mn, S, P and other elements, but SS400 only requires S and P to be less than 0.050. The yield point of Q235 is greater than 235 MPa, while the yield point of SS400 is 245 MPa. SS400 (steel for general structure) means general structural steel with a tensile strength greater than 400MPa. Q235 means ordinary carbon structural steel with a yield point greater than 235MPa. The standard number of SS400 is JIS G3101. The standard number of Q235 is GB/T700.

SS400 is a marking method of Japanese steel, which is actually the domestic Q235 steel. It is a kind of steel material. Q represents the yield of this material, the latter 235 refers to the yield value of this material, around 235. And as the thickness of the china carbon steel coil material increases, its yield value decreases. Due to the moderate carbon content, the comprehensive performance is better, the strength, plasticity and welding properties are better matched, and the application is the most extensive. Often rolled into wire rod or round steel, square steel, flat steel, angle steel, I-beam steel, channel steel, window frame steel and other section steels, medium and thick steel plates. It is widely used in construction and engineering structures. It is used to make steel bars or to build factory buildings, high-voltage power transmission towers, bridges, vehicles, boilers, vessels, ships, etc., and also a large number of mechanical parts with low performance requirements. C and D grade steel can also be used as some professional steel.

Factory appearance

Packing & Delivery

Our Company

Shandong Chengming Steel Co.,Ltd

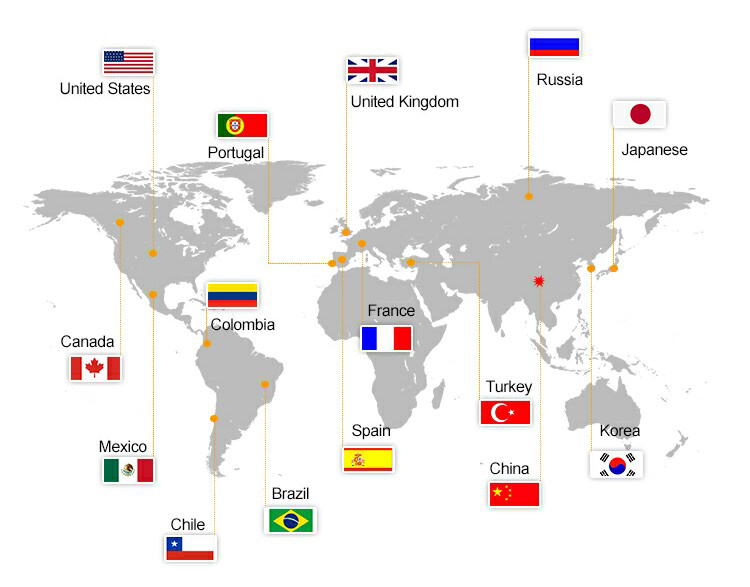

Our company supplies cold/hot-rolled stainless steel sheets,stainless steel bars ,stainless steel coil stainless steel pipes,lead plate,bearing steel,spring steel,steel plate pile,tank plate,alloy steel plate,weather resistant steel plate and wear resistant plate to many steel factories from at home and abroad, including Shanxi Taigang Iron& Steel CO,.LTD (TISCO) Zhangjiagang Pohang (ZPSS), Shanghai Krupp, Ningbo Baoxin and steel factories in Taiwan area, Mainland Chinese and foreign countries and regions.

Our annual capacity is 25, 000 tons. The Annual Domestic Sale is 20 million, Annual Exported Sale about 12 million dollars.Our products supplied to more than 20 countries, such as Indonesia, Spain, Japan, Korea, Vietnam, Italy, Israel,Australia, Malaysia, Brazil, Pakistan, U. A. E, Peru, India etc. Good quality has been getting more and more prise from buyers at home and abroad.Our long-term business lines are 304 .202, 201 .430.409L, 304L, 316L, 309S and 310S, Finish: 2B ,BA ,NO.1 NO.4 ,HL, NO.8 and so on . For the sheets and coils,the thickness ranging from 0.3mm to 100mm.For the bars,the diameter ranging from 1mm to 300mm.For the pipes ,we have seamless pipe and weld pipe. Meanwhile, our company is also engaged in the long-term supply of homemade & imported medium and thick plates,galvanized or carbon

ONLINE MESSAGE

RELATED PRODUCTS

Steel Sheet pile Description The steel sheet pile is a kind of steel structure with a linkage device on the edge, and this linkage device can be freely combined to form a continuous and compact steel structure with a retaining wall or a water retaining wall. The steel sheet pile is a type of steel with a lock. Its cross-sections are straight, trough and Z-shaped. There are various sizes and interlocking forms. The common ones are Larsonian, Lakwanaian and so on. Its advantages are: high strength, easy to penetrate hard soil; can be constructed in deep water, if necessary, add diagonal support to become a cage. It has good waterproof performance; it can be formed into cofferdams of various shapes as required and can be reused many times. Therefore, it has a wide range of uses. classification Steel sheet pile products are classified into cold-formed thin-walled steel sheet piles and hot-rolled steel sheet piles according to the production process. (1) There are two types of cold-formed steel sheet piles: non-bite type cold-formed steel sheet piles (also called channel plates) and bite type cold-formed steel sheet piles (divided into L-shaped, S-shaped, U-shaped, and Z-shaped) . Production process: Use thinner plates (commonly used thickness 8mm ~ 14mm) to be continuously rolled and formed in the cold bending unit. Advantages: less investment in the production line, lower production cost, flexible control of product size. Disadvantages: the thickness of each part of the pile body is the same, the section size cannot be optimized, which leads to an increase in steel consumption, the shape of the lock part is difficult to control, the joint is not tightly buckled, and the water cannot be stopped, and the pile body is easy to tear during use. (2) Hot-rolled steel sheet piles Hot-rolled steel sheet piles in the world mainly include U-shaped, Z-shaped, AS-shaped, H-shaped and dozens of specifications. The production, processing and installation processes of Z-type and AS-type steel sheet piles are relatively complicated, and are mainly used in Europe and America; U-type steel sheet piles are mainly used in China. Production process: It is formed by high temperature rolling by a section steel rolling mill. Advantages: standard size, superior performance, reasonable cross-section, high quality, and tight water barrier for the lock bite. Disadvantages: technical difficulty is relatively high, production cost is relatively high, specification series are not flexible. In engineering construction, the application range of cold-formed steel sheet piles is relatively narrow, and most of them are used as supplementary materials for applications. Hot-rolled steel sheet piles have always been the leading product for engineering applications. Based on the many advantages of steel sheet piles in construction operations, the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China and the National Standardization Management Committee issued the national standard for "Hot Rolled U-shaped Steel Sheet Pile" on May 14, 2007, and on December 1, 2007 Formally implemented. At the end of the 20th century, Maanshan Iron & Steel Co., Ltd. produced more than 5,000 tons of U-shaped steel sheet piles with a width of 400mm with the introduction of the universal rolling mill production line from abroad. The U-shaped steel sheet piles were successfully used in the cofferdam of Nenjiang Bridge and the 300,000 tons of Jingjiang New Century Shipyard. Ton shipyard and Bangladesh flood control projects. However, due to the low production efficiency, poor economic efficiency, low domestic demand and insufficient technical experience during the trial production period, continuous production was not possible. According to statistics, the annual consumption of steel sheet piles in my country remains at about 30,000 tons, accounting for only 1% of the world’s total, and it is limited to permanent projects such as the construction of some ports, wharves, and shipyards, as well as the construction of bridges, cofferdams, and foundation pit support Temporary works. The cold-formed steel sheet pile is continuously rolled and formed by the cold-formed unit, and the side lock can be continuously overlapped to form a steel structure of the sheet pile wall. The cold-formed steel sheet pile is made of thinner plates (commonly used thickness is 8mm-14mm) and processed by cold-formed forming units. The production cost is lower and the price is cheap, and the fixed-length control is more flexible. However, due to the simple processing method, the thickness of each part of the pile body is the same, the cross-sectional size cannot be optimized, which leads to an increase in steel consumption; the shape of the lock part is difficult to control, the joint is not tightly buckled, and the water cannot be stopped; limited by the capacity of cold bending processing equipment, It can produce low-strength ste

The steel sheet pile is a kind of steel structure with a linkage device on the edge, and this linkage device can be freely combined to form a continuous and compact steel structure with a retaining wall or a water retaining wall.

Stainless steel round steel belongs to the category of long products and bars. The so-called stainless steel round steel refers to a long product with a uniform circular cross section